Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

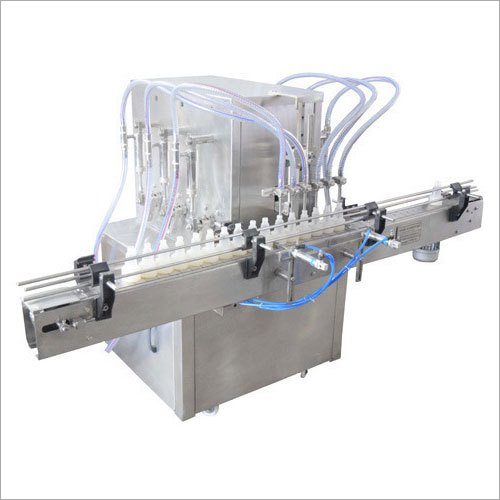

LIQUID FILLING MACHINE

Product Details:

- Product Type AUTOMATIC

- Application Chemical Food Medical Beverage

- Packaging Material Metal

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Drive Type Electric

- Click to View more

LIQUID FILLING MACHINE Price And Quantity

- 1 Unit

LIQUID FILLING MACHINE Product Specifications

- Automatic

- 1

- Electric

- 52X38X90 Inch (in)

- 100 Kilograms (kg)

- Chemical Food Medical Beverage

- Yes

- 240 Volt (v)

- Metal

- 36000 Pcs/hr

- PLC Control

- Blue

- AUTOMATIC

- High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency Stable Performance Simple Control

LIQUID FILLING MACHINE Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Automatic Liquid Filling Machine “ Fast, Accurate & Clean Filling for High-Volume Production

An Automatic Liquid Filling Machine is designed for fast and precise filling of low to high-viscosity liquids into bottles, jars, and containers without spillage or contamination. Ideal for industries such as beverages, edible oils, pharmaceuticals, cosmetics, and chemicals, this machine automates the filling process, reduces human error, and increases production efficiency. Whether you're handling water, syrups, hand sanitizers, or shampoo, this machine ensures every drop counts”boosting speed, accuracy, and hygiene.

Technical Specifications of Automatic Liquid Filling Machine

(Specifications may vary depending on the model “ here™s a standard overview)

| Specification | Details |

|---|---|

| Filling Range | 50 ml to 1000 ml / 100 ml to 5000 ml |

| Number of Filling Heads | 2 / 4 / 6 / 8 / 12 heads (customizable) |

| Filling Speed | Up to 30“120 bottles per minute |

| Filling Accuracy | ±1% (depending on product and volume) |

| Filling Type | Volumetric / Servo-driven / Flowmeter-based |

| Container Type | PET, HDPE, Glass, etc. |

| Nozzle Type | Anti-drip / Diving nozzles (for foamy liquids) |

| Power Supply | 220V / 380V, 50/60 Hz, 3 Phase |

| Air Consumption | 4-6 Bar (for pneumatic models) |

| Control System | PLC-based with Touchscreen HMI |

| Construction Material | SS 304 / SS 316 (for contact parts) |

| Conveyor | SS Slat Conveyor with Adjustable Guide |

| Optional Add-ons | Capping, Labeling, Rinsing Unit |

Top SEO-Optimized FAQs for Automatic Liquid Filling Machine

1. What is an automatic liquid filling machine used for?

An automatic liquid filling machine is used for filling various liquid products”such as juices, oils, syrups, and cleaning solutions”into containers accurately and efficiently on a large scale.

2. Which industries benefit from automatic liquid filling machines?

Industries such as food & beverage, pharmaceuticals, personal care, cosmetics, agrochemicals, and lubricants benefit greatly from the speed and hygiene offered by automatic liquid filling machines.

3. Can the machine handle thick or foamy liquids?

Yes, advanced models with diving nozzles and servo control can easily handle viscous or foamy liquids like shampoo, honey, sanitizer gel, and lotion.

4. How accurate is the filling process?

Automatic liquid filling machines offer filling accuracy of ±1%, ensuring consistent volume in each container and reducing product wastage.

5. How many bottles per minute can this machine fill?

Depending on the number of filling heads and liquid type, the machine can fill between 30 to 120 bottles per minute.

6. Is this machine compatible with different bottle sizes?

Yes, it supports a wide range of bottle types and sizes with simple tool-less changeovers, making it suitable for varied production requirements.

7. Does it come with an integrated capping and labeling system?

Optional attachments like automatic capping machines and labeling units can be added to create a complete packaging line.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+