Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

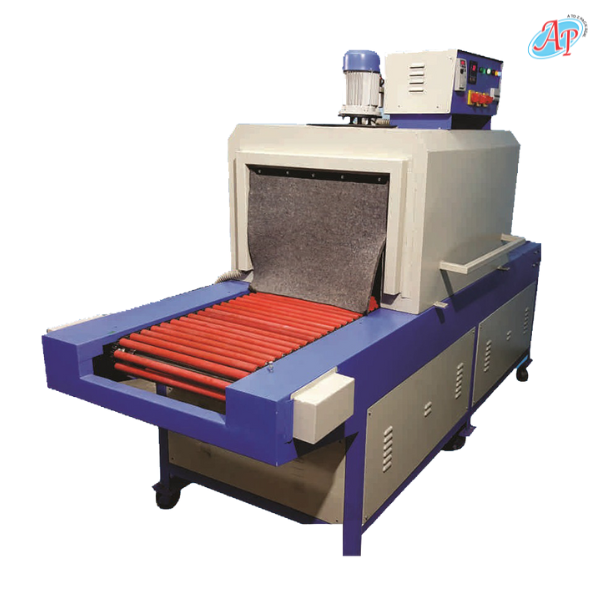

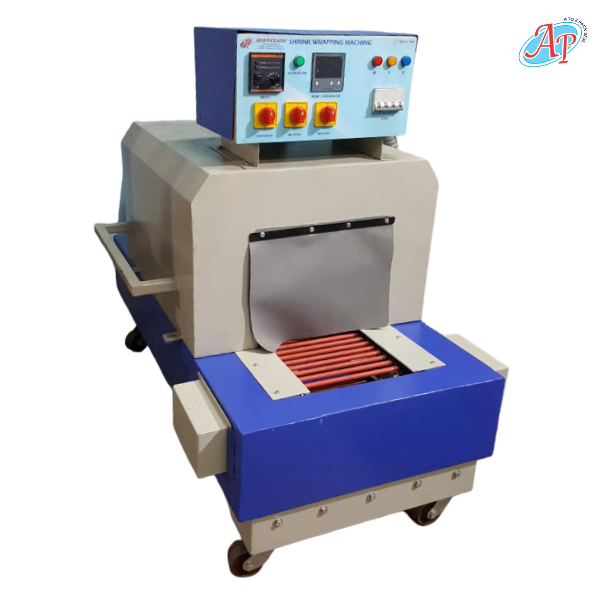

cream tube shrink tunnel machine

Product Details:

- Type SEMI AUTOMATIC SHRINK WRAPPING MACHINE

- Material MS / SS

- Automatic Grade Semi-Automatic

- Shrink Speed AS PER PRODUCT SIZE AND OPERATOR

- Voltage 220 Volt (v)

- Dimension (L*W*H) 48x8x8 Inch (in)

- Weight 50 Kilograms (kg)

- Click to View more

cream tube shrink tunnel machine Price And Quantity

- 1 Unit

- 86500 INR/Unit

cream tube shrink tunnel machine Product Specifications

- AS PER PRODUCT SIZE AND OPERATOR

- 1 YEAR

- SEMI AUTOMATIC SHRINK WRAPPING MACHINE

- 50 Kilograms (kg)

- 220 Volt (v)

- GREY & BLUE

- MS / SS

- 48x8x8 Inch (in)

- Semi-Automatic

cream tube shrink tunnel machine Trade Information

- Cash Against Delivery (CAD), Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

The Cream Tube Shrink Tunnel Machine by AmarPack Machines Pvt. Ltd. is specifically designed for achieving perfect shrink wrapping on cosmetic and pharmaceutical cream tubes. The machine uses advanced hot air circulation technology to evenly distribute heat across the shrink film, resulting in smooth, wrinkle-free packaging.

It features digital temperature control, variable conveyor speed, and a compact stainless-steel tunnel body, ensuring durability and hygiene a critical requirement in the cosmetic and pharmaceutical industries. This tunnel can be easily integrated with manual, semi-automatic, or fully automatic shrink wrapping lines.

Standard Technical Details

| Specification | Details |

|---|---|

| Power Supply | 415V AC, 50Hz, 3 Phase |

| Temperature Range | 50C 250C (Adjustable) |

| Conveyor Speed | Variable (0-10 m/min) |

| Tunnel Size | 1000 mm (L) 450 mm (W) 200 mm (H) |

| Machine Body | SS304 or Powder-Coated Mild Steel |

Key Features

-

Uniform Heat Circulation: Dual blower system for consistent shrink results.

-

Energy-Efficient Design: Quick heat-up and low power consumption.

-

Digital Control System: Adjustable speed and temperature with precise control.

-

Hygienic Build: Stainless steel option suitable for pharma & cosmetic plants.

-

Low Maintenance: Robust design ensures continuous long-hour operation.

Suitable Products

-

Cosmetic Cream Tubes: Moisturizers, lotions, and face creams.

-

Ointment Tubes: Pharmaceutical and medical creams.

-

Personal Care Tubes: Sunscreens, gels, and haircare products.

-

Toothpaste & Gel Tubes: Clear and secure packaging for FMCG goods.

Applications

-

Cosmetic & Skincare Manufacturing Units

-

Pharmaceutical Formulation Plants

-

FMCG Packaging Units

-

Contract & Export Packaging Companies

Benefits

-

Ensures smooth, wrinkle-free shrink wrapping for premium product appearance.

-

Protects tubes from external contamination and leakage.

-

Easy integration with existing filling and sealing lines.

-

Compact design ideal for small to medium-scale packaging setups.

-

Reduces manual labor and enhances production efficiency.

FAQs

Q1. What is the main purpose of this machine?

It ensures tamper-proof, hygienic, and visually appealing packaging for cream and ointment tubes.

Q2. Which films are compatible?

PVC, POF, and LDPE shrink films with thicknesses between 25-50 microns are compatible.

Q3. Can the machine handle multiple tube sizes?

Yes, adjustable conveyor and tunnel height make it suitable for various tube diameters and lengths.

Q4. Is it suitable for continuous operation?

Yes, the machine is designed for 24x7 operation with efficient temperature control and minimal maintenance.

Q5. Does it require skilled labor to operate?

No, it features an easy-to-use control panel with minimal operator training required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+