Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

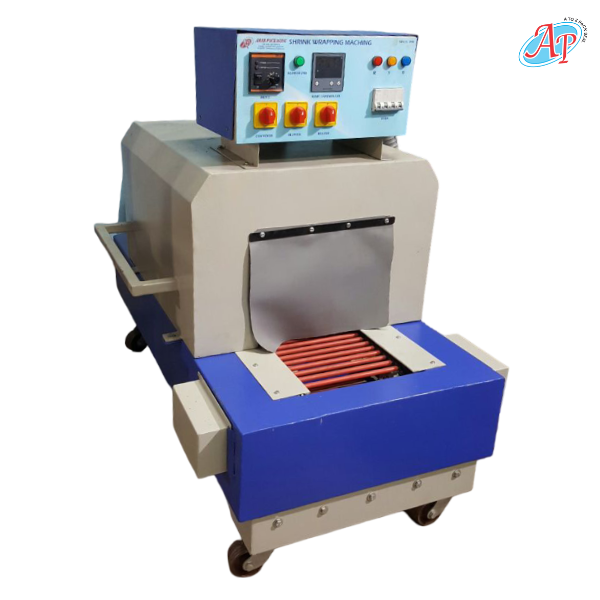

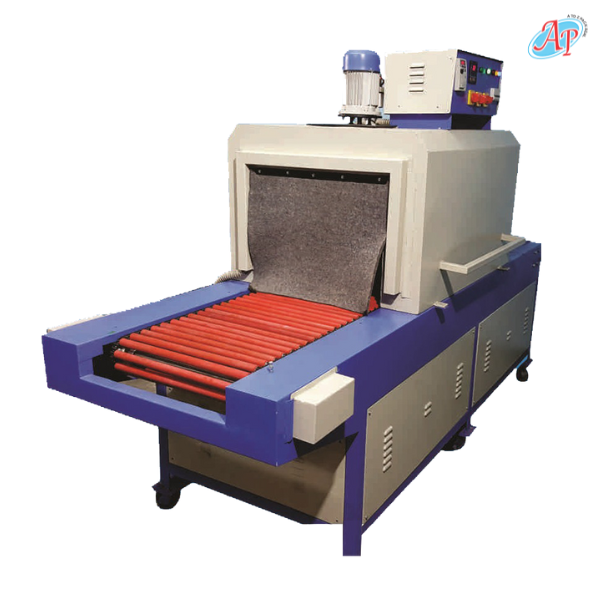

pharma bottle automatic shrink wrapping machine

Product Details:

- Type SEMI AUTOMATIC SHRINK WRAPPING MACHINE

- Material MS / SS

- Computerized No

- Automatic Grade Automatic

- Control System Frequency Speed Control

- Shrink Speed AS PER PRODUCT SIZE AND OPERATOR

- Voltage 220 Volt (v)

- Click to View more

pharma bottle automatic shrink wrapping machine Price And Quantity

- 186500 INR/Unit

- 1 Unit

pharma bottle automatic shrink wrapping machine Product Specifications

- 130 Kilograms (kg)

- AS PER PRODUCT SIZE AND OPERATOR

- Frequency Speed Control

- Automatic

- 60x16x14 Inch (in)

- MS / SS

- SEMI AUTOMATIC SHRINK WRAPPING MACHINE

- No

- GREY & BLUE

- 220 Volt (v)

- 1 YEAR

pharma bottle automatic shrink wrapping machine Trade Information

- Cash Against Delivery (CAD), Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

The Pharma Bottle Automatic Shrink Wrapping Machine from AmarPack Machines Pvt. Ltd. is designed for high-speed, consistent, and precise packaging of pharmaceutical bottles and containers. This automatic system integrates seamlessly into existing production lines, ensuring tamper-evident and durable packaging that maintains hygiene and compliance with pharma industry standards.

The system automatically collates bottles, wraps them in heat-sensitive shrink film, and conveys them through a controlled shrink tunnel to achieve tight, wrinkle-free sealing. The design minimizes operator intervention while maximizing throughput, making it ideal for pharmaceutical, nutraceutical, and healthcare product packaging.

Standard Technical Details

| Specification | Details |

|---|---|

| Power Supply | 415V, 50Hz, 3 Phase |

| Film Type | LDPE / PVC / POF Heat Shrink Film |

| Machine Dimensions | Approx. 3000mm (L) x 900mm (W) x 1500mm (H) |

| Speed | Up to 30 packs/minute |

| Temperature Control | Digital PID with automatic control |

Key Features

-

Automatic Bottle Grouping & Wrapping: Designed for inline pharma bottle packing without manual handling.

-

High-Speed Shrink Tunnel: Ensures uniform heat distribution for smooth and wrinkle-free film finish.

-

Hygienic Design: Stainless steel frame suitable for cleanroom environments.

-

Energy Efficient: Advanced insulation reduces power consumption.

-

Customizable: Can be configured for different bottle sizes, shapes, and bundle quantities.

Suitable Applications

-

Pharmaceutical bottles and jars

-

Nutraceutical syrup bottles

-

Cosmetic containers

-

Healthcare product packaging

FAQs

Q1. What types of films can this machine use?

It supports LDPE, PVC, and POF shrink films of varying thicknesses as per pharma-grade packaging requirements.

Q2. Can it integrate with existing production lines?

Yes, the automatic shrink wrapper can easily connect with filling, labeling, and capping systems.

Q3. Is this machine GMP compliant?

Yes, all contact parts and frame designs follow GMP-compliant standards for pharmaceutical manufacturing.

Q4. What is the maintenance requirement?

Minimal maintenance ” occasional lubrication and periodic inspection ensure years of reliable performance.

Q5. What industries use this machine?

Pharmaceutical, nutraceutical, cosmetic, and healthcare product manufacturing industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+