Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

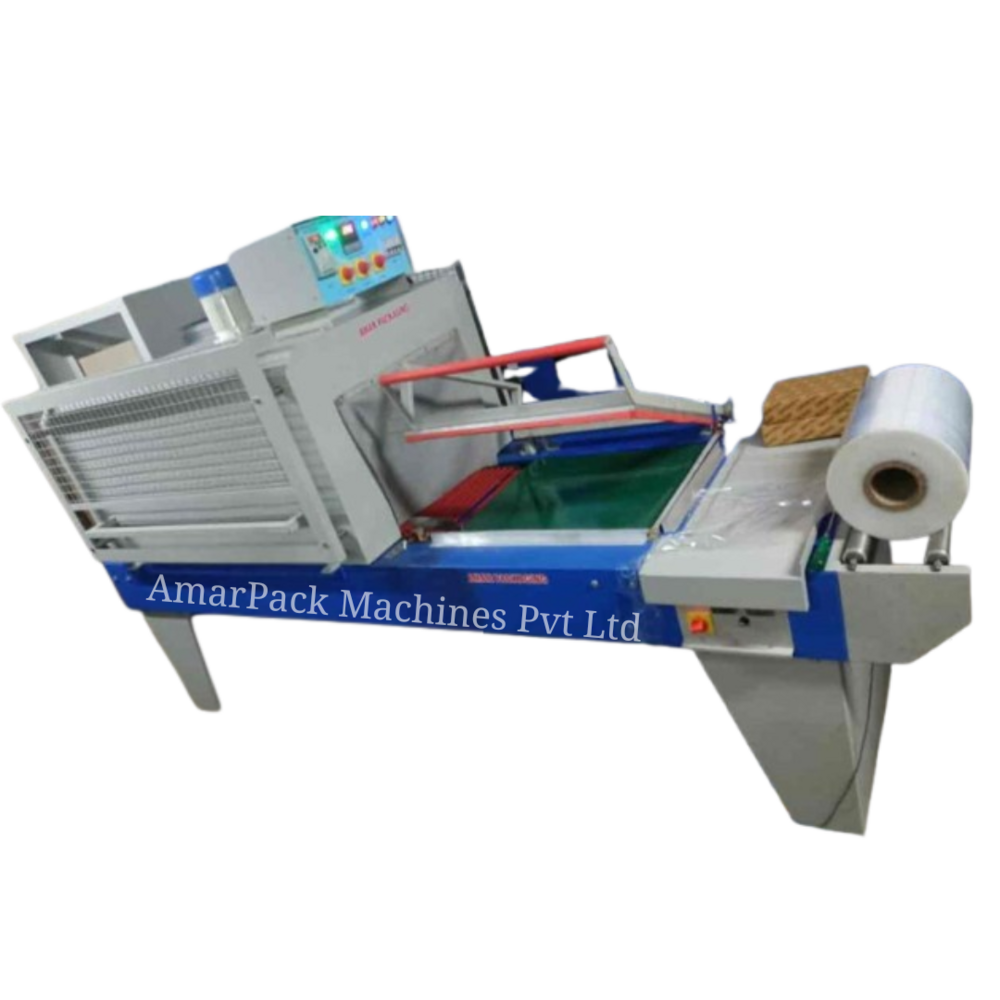

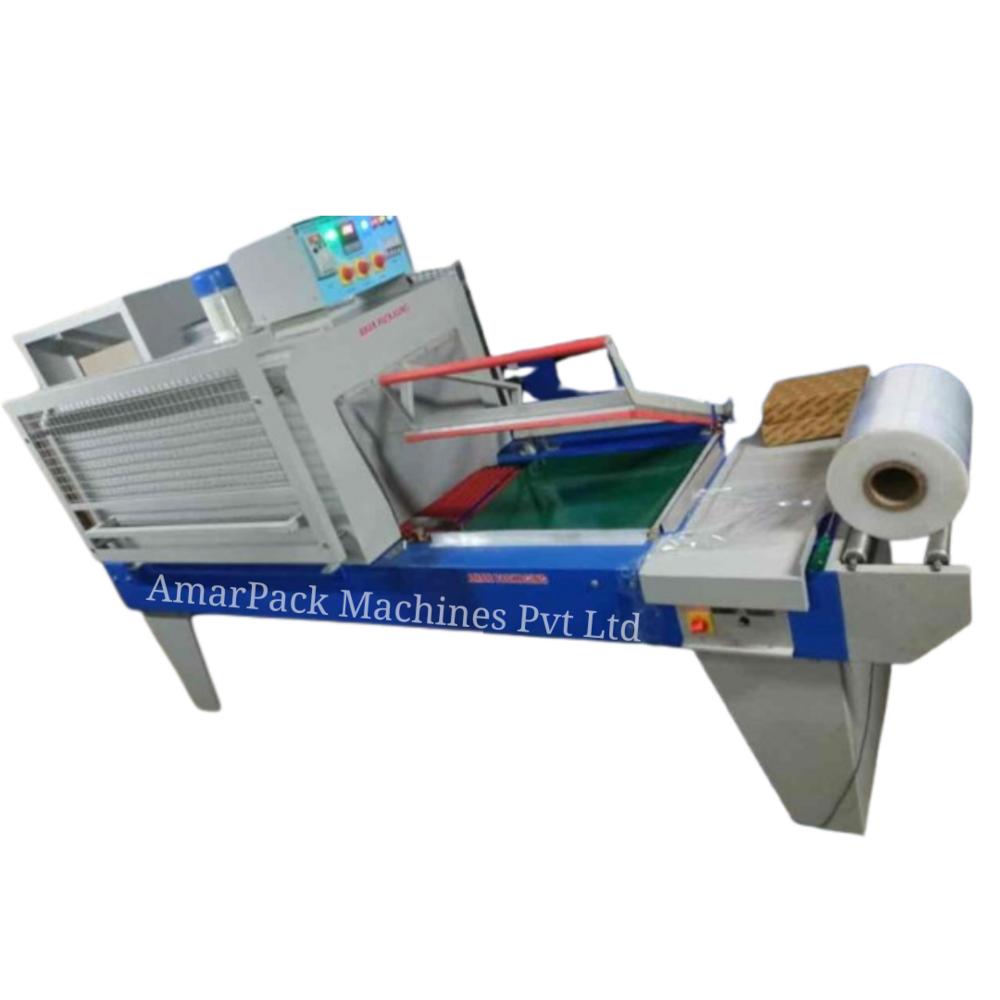

PNEUMATIC L-SEALER WITH SHRINK TUNNEL MACHINE

Product Details:

- Type Pneumatic Sealing Machine

- Material MS

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Voltage 110-215 Volt (v)

- Warranty 1 Year

- Click to View more

PNEUMATIC L-SEALER WITH SHRINK TUNNEL MACHINE Price And Quantity

- 330000 INR/Unit

- 1 Unit

PNEUMATIC L-SEALER WITH SHRINK TUNNEL MACHINE Product Specifications

- Pneumatic Sealing Machine

- Human Machine Interface

- Automatic

- No

- 1 Year

- MS

- 110-215 Volt (v)

PNEUMATIC L-SEALER WITH SHRINK TUNNEL MACHINE Trade Information

- Cash on Delivery (COD), Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

A Pneumatic LSealer with Shrink Tunnel Machine is an advanced semiautomatic solution designed for faster precise and efficient shrink wrapping This machine is ideal for businesses that require highspeed packaging with minimal manual effort It helps businesses by

Enhancing Productivity Uses a pneumatic system for faster and more efficient sealing

Reducing Labor Effort Automated sealing reduces manual workload and increases output

Ensuring Professional Packaging Creates a clean tight and tamperproof seal for superior product presentation

Protecting Products Shields items from dust moisture and external damage

Versatile Applications Suitable for food pharmaceuticals cosmetics electronics and retail packaging

Technical Details of Pneumatic LSealer with Shrink Tunnel

1 Machine Type Pneumatic LSealer with Shrink Tunnel

2 Power Supply 220V 5060Hz Single Phase or 440V Three Phase

3 Power Consumption 5 8 kW Varies by model

4 Sealing Area 18 x 24 Custom sizes available

5 Shrink Tunnel Conveyor Tefloncoated belt or roller conveyor

6 Tunnel Size 12 x 16 or as per requirement

7 Shrink Film Type PVC Polyolefin or LDPE Shrink Films

8 Max Film Thickness 25 100 microns

9 Sealing Mechanism Pneumatic pressurebased sealing system

Production Speed 15 30 packs per minute varies by product size

11 Weight Approx 200500 kg

12 Application Ideal for packaging boxes bottles printed materials and industrial goods

This highperformance packaging machine is perfect for businesses looking to increase speed reduce manual work and achieve professional shrinkwrapped packaging

Effortless Sealing and Shrink Wrapping

The pneumatic L-sealer with shrink tunnel machine offers streamlined packaging with minimal manual intervention. Automated operation and intuitive Human Machine Interface make daily use easy and efficient, catering to a range of businesses from traders to large-scale manufacturers.

Durable MS Construction

Crafted from high-quality mild steel, this machine delivers long-lasting reliability even under demanding industrial conditions. Its robust build ensures optimal operation, while the 1-year warranty provides peace of mind regarding durability and after-sales support.

FAQs of PNEUMATIC L-SEALER WITH SHRINK TUNNEL MACHINE:

Q: How does the pneumatic L-sealer with shrink tunnel machine operate?

A: This automatic machine uses compressed air to drive the sealing mechanism, followed by a shrink tunnel that applies heat to wrap products neatly in shrink film. The integrated Human Machine Interface allows operators to control settings effectively.Q: What materials can be packaged using this machine?

A: The machine is suitable for various products that require shrink-wrapped packaging, using compatible shrink films. Its versatile design caters to the needs of industries such as manufacturing, exporting, and wholesaling in India.Q: When is the best time to use this pneumatic sealing machine?

A: This machine is ideal for use during the final packaging stage, especially when high throughput and consistent sealing quality are required in commercial or industrial operations.Q: Where can the pneumatic L-sealer with shrink tunnel machine be installed?

A: Designed for flexibility, the machine can be installed in manufacturing facilities, warehouses, export houses, and distribution centers across India, requiring only standard electrical connections and space for operation.Q: What is the process involved with sealing and shrinking products?

A: The process begins with placing the product inside shrink film, the L-sealer seals the film around the product using pneumatic pressure, and the product then passes through the shrink tunnel for a tight, professional finish.Q: How does the Human Machine Interface benefit users?

A: The Human Machine Interface simplifies machine operation by offering easy-to-understand controls and real-time adjustments, improving productivity and reducing the likelihood of operator error.Q: What are the key benefits of using this machine for suppliers and traders?

A: Suppliers and traders gain faster, automated packaging, lower labor costs, and improved packaging consistency, which all contribute to enhanced business throughput and customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+