Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

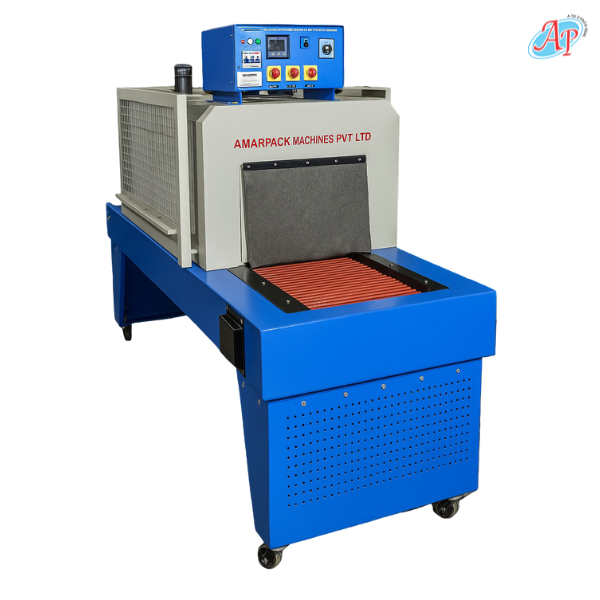

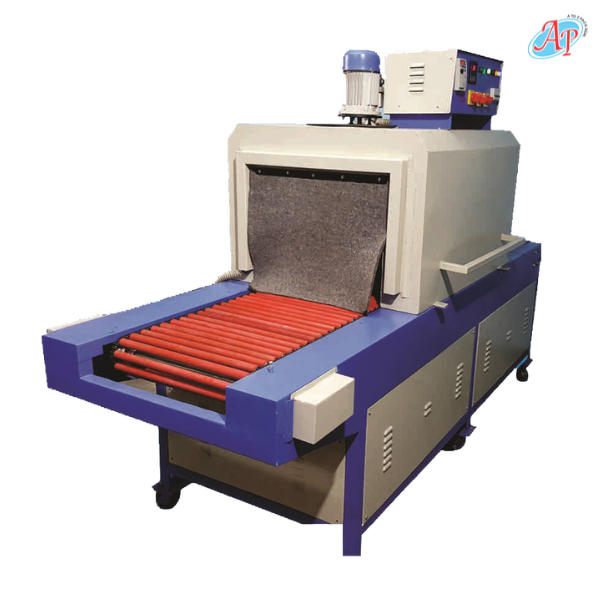

Semi Automatic Shrink Wrapping Machine

Product Details:

- Type SHRINK WRAP

- Material STAINLESS STEEL

- Capacity 10 UNIT PER MINUTE Kg/hr

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Voltage 220-240 Volt (v)

- Click to View more

Semi Automatic Shrink Wrapping Machine Price And Quantity

- 1 Unit

- 350000.00 INR/Unit

Semi Automatic Shrink Wrapping Machine Product Specifications

- 150 Kilograms (kg)

- STAINLESS STEEL

- 10 UNIT PER MINUTE Kg/hr

- WHITE BLUE

- 24x16x60 Inch (in)

- 1

- PLC Control

- Yes

- SHRINK WRAP

- 220-240 Volt (v)

- Semi-Automatic

Semi Automatic Shrink Wrapping Machine Trade Information

- Cash on Delivery (COD), Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

The Semi-Automatic Shrink Wrapping Machine by AmarPack Machines Pvt Ltd is an efficient and cost-effective solution for medium-scale packaging operations. It is designed to wrap products in shrink film and apply heat to create a secure, tamper-proof seal. This machine is perfect for industries such as food & beverage, pharmaceuticals, FMCG, cosmetics, and e-commerce, ensuring high-quality packaging with minimal labor effort.

With a semi-automatic system, operators need to manually place the product and activate the sealing process, while the machine automatically applies heat to shrink the film. It provides a professional finish, product protection, and increased shelf life.

Key Benefits:

Ideal for small to medium production units

Protects products from dust, moisture, and damage

Energy-efficient and cost-effective solution

Compatible with multiple product sizes and shapes

Ensures tamper-proof and professional shrink wrapping

Frequently Needed Questions (FNQs)

1 What is a Semi-Automatic Shrink Wrapping Machine?

It is a partially automated shrink wrapping system where the operator manually places the product, activates the sealing, and the machine applies heat to shrink the film, securing the packaging.

2 How does it work?

1 The operator places the product on the sealing area.

2 The machine wraps shrink film around the product.

3 The operator presses a button to activate the sealing.

4 The sealed product moves into the heat tunnel, where the film shrinks tightly around it.

5 The final product exits, ready for distribution or storage.

3 Which industries benefit from this machine?

-

Food & Beverage Bottles, cans, packaged snacks

-

Pharmaceuticals Medicine boxes, medical kits

-

E-commerce & Retail Books, electronics, cosmetics

-

FMCG & Consumer Goods Personal care, household products

-

Printing & Stationery Magazines, notebooks, paper reams

4 What types of shrink films can be used?

-

Polyolefin Shrink Film Strong, flexible, and eco-friendly

-

PVC Shrink Film Lightweight and cost-effective

-

Polyethylene Shrink Film Ideal for bulk and heavy-duty packaging

5 What are the key advantages of this machine?

Easy to operate with minimal training

Reduces labor effort while ensuring consistent packaging quality

Compact design suitable for small and medium businesses

Cost-effective compared to fully automatic models

Enhances product presentation and durability

6 Can it handle different product sizes and shapes?

Yes! The adjustable sealing system allows it to accommodate a variety of product dimensions.

7 Is the machine easy to operate?

Yes! It features a simple control panel, allowing operators to adjust sealing time, temperature, and speed easily.

8 What are the power requirements?

Most models operate on 220V440V, single-phase or three-phase power supply, depending on machine specifications.

9 How durable is the shrink wrapping?

Shrink-wrapped products are protected from external damage, moisture, and tampering, ensuring long-lasting durability and a professional finish.

How do I choose the right Semi-Automatic Shrink Wrapping Machine?

To select the best machine, consider:

Production volume & speed requirements

Type of products being packaged

Shrink film type & thickness

Available space for installation

Efficient Packaging Solution

Designed to streamline packaging workflows, this machine delivers consistent shrink wrapping at a rate of 10 units per minute. The semi-automatic functionality allows operators to manage different packaging sizes and materials effortlessly, increasing productivity and reducing manual labor.

Advanced Control System

Equipped with PLC controls and computerized settings, this shrink wrapping machine offers precise temperature and speed adjustments. Its user-friendly interface supports quick setup and operational changes, making it adaptable to a wide range of packaging requirements.

Durability and Design

Crafted from high-grade stainless steel, the machine resists corrosion and wear, ensuring long-lasting operation in demanding industrial environments. Its compact design fits well within existing production floors, and the white-blue finish adds a modern industrial touch.

FAQs of Semi Automatic Shrink Wrapping Machine:

Q: How does the Semi Automatic Shrink Wrapping Machine operate?

A: This machine combines computerized and PLC-controlled mechanisms to automatically wrap products in shrink film. Operators load the products, adjust settings as needed, and the machine wraps and seals the items, allowing for semi-automatic management of the packaging process.Q: What materials can be shrink-wrapped using this machine?

A: The machine is compatible with standard shrink films, such as polyolefin and PVC, making it suitable for packaging various consumer goods, boxes, and industrial products. The stainless steel build supports continuous use with diverse film types.Q: When should this shrink wrapping machine be used in a production line?

A: Its ideal for inclusion after product assembly and before storage or shipping. The machine efficiently wraps finished goods, protecting them from dust, moisture, and tampering during transit and storage.Q: Where is the best location to install this machine in a factory setup?

A: With dimensions of 24x16x60 inches, it is best positioned near the end of the production line, where products are readied for packaging. Its manageable footprint allows integration into various industrial environments across India.Q: What is the shrink wrapping process with this machine?

A: Products are placed on the conveyor, shrink film is wrapped around them, and heat is applied to conform the film tightly. The machine controls parameters such as speed and temperature, resulting in secure, uniform packaging.Q: How does using this machine benefit manufacturers and suppliers?

A: This machine enhances operational efficiency, reduces packaging time, and lowers labor costs. Its reliable sealing and compact packaging improve product presentation and protection, benefiting dealers, distributors, exporters, and manufacturers alike.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+