Talk To Expert :- 08045800426

Talk To Expert :- 08045800426

Working hours:

Mon-Fri:9.00am to 5.00pm

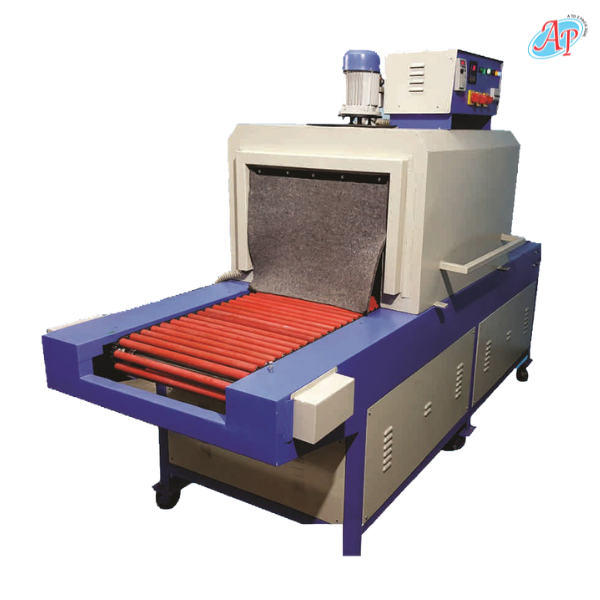

Shrink wrap system

Product Details:

- Type Automatic Shrink Wrap System

- Material Stainless Steel

- Capacity Up to 25 packs/min

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Controlled

- Shrink Speed Adjustable up to 25 packs/min

- Click to View more

Shrink wrap system Price And Quantity

- 1860000 INR/Unit

- 1 Unit

- 500 mm x 400 mm x 300 mm

- 4.5 kW

- 5C to 40C

- 70 dB

- Heavy-duty Castor Wheels

- PVC, Polyolefin, PE

- Adjustable

- Adjustable 0~250C

- Emergency Stop, Overheat Protection

- Heat Insulated Stainless Steel

Shrink wrap system Product Specifications

- 2450 mm x 900 mm x 1530 mm

- Stainless Steel

- Automatic

- Max. 400 mm

- Up to 25 packs/min

- 500 kg (approx.)

- 220-240V, 50/60Hz

- Yes

- 6-8 bar

- PLC Controlled

- Silver/Grey

- Adjustable up to 25 packs/min

- Automatic Shrink Wrap System

- 500 mm x 400 mm x 300 mm

- 4.5 kW

- 5C to 40C

- 70 dB

- Heavy-duty Castor Wheels

- PVC, Polyolefin, PE

- Adjustable

- Adjustable 0~250C

- Emergency Stop, Overheat Protection

- Heat Insulated Stainless Steel

Shrink wrap system Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 5 Unit Per Month

- 30 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

A shrink wrap system is a packaging solution that uses heat to shrink a plastic film tightly around a product. This system is widely used in industries such as food, pharmaceuticals, retail, and manufacturing to provide secure, tamper-evident, and professional-looking packaging.

The system typically includes:

- Shrink film (PVC, Polyolefin, or PE)

- Sealing unit (L-bar sealer, impulse sealer, etc.)

- Shrink tunnel or heat gun for applying heat to shrink the film

Frequently Asked Questions (FAQs)

1. How does a shrink wrap system work?

A shrink wrap system works by wrapping a product in a heat-sensitive plastic film and then applying heat, causing the film to shrink and tightly conform to the shape of the item.

2. What types of shrink wrap machines are available?

Shrink wrap systems come in several types:

- Manual Shrink Wrappers Best for small-scale operations

- Semi-Automatic Shrink Wrappers Suitable for medium production levels

- Fully Automatic Shrink Wrap Machines Ideal for large-scale industrial packaging

3. What materials are used in shrink wrapping?

Common shrink films include:

- PVC (Polyvinyl Chloride) Cost-effective but not eco-friendly

- Polyolefin (POF) Strong, durable, and food-safe

- Polyethylene (PE) Used for heavy-duty applications

4. What are the benefits of shrink wrapping?

- Protection Shields products from dust, moisture, and tampering

- Durability Strong film ensures product safety during transportation

- Professional Appearance Provides a clean and polished packaging finish

- Cost-Effective Requires minimal materials compared to other packaging methods

5. Can shrink wrapping be used for food packaging?

Yes! Food-safe shrink wrap films like Polyolefin (POF) are commonly used in packaging food items like fruits, baked goods, and frozen products.

6. What is the difference between shrink wrap and stretch wrap?

- Shrink Wrap Uses heat to shrink film tightly around a product

- Stretch Wrap Uses tension to stretch film around an item without heat

7. How long does shrink wrap last?

Shrink wrap durability depends on the film type and storage conditions, but high-quality shrink film can last for several months to years without degradation.

8. Is shrink wrap recyclable?

Some types, like Polyolefin (POF) and Polyethylene (PE), are recyclable, while PVC shrink wrap is not eco-friendly and should be disposed of properly.

9. How do I choose the right shrink wrap system?

Consider:

- Product Size & Shape Choose the right film thickness & machine size

- Production Volume Manual for small-scale, automatic for high-speed packaging

- Budget Cost varies based on machine type and film material

10. Where can I buy a shrink wrap system?

Shrink wrap machines and materials are available from industrial packaging suppliers, online marketplaces, and specialized equipment manufacturers.

High Performance and Versatility

Enjoy the efficiency of a shrink wrap system capable of sealing up to 25 packs each minute. Its adjustable conveyor speed and sealing temperature allow you to seamlessly package a variety of products of different sizes, optimizing output in any production environment while ensuring reliability.

Safety and Durability

Built with heat insulated stainless steel and integrated safety features, including overheat protection and an emergency stop, this shrink wrap system promises lasting durability and operator security. Its heavy-duty castor wheels make relocation easy within your workspace.

Adaptable Film Compatibility

Whether you use PVC, Polyolefin, or PE films, this system accommodates your packaging preferences. With computerized PLC controls and adjustable shrink speed, it ensures consistent wrapping quality and adaptability for diverse applications.

FAQ's of Shrink wrap system:

Q: How does the automatic shrink wrap system adjust to varying product sizes?

A: The system features an ample chamber and flexible conveyor, allowing it to accommodate products up to 500 mm x 400 mm x 300 mm. Adjustable settings ensure secure and seamless wrapping regardless of the product's dimensions within these limits.Q: What are the benefits of using this shrink wrap system in industrial settings?

A: This system offers high throughput (up to 25 packs per minute), customizable sealing temperatures, and compatibility with multiple packaging films. These features, combined with advanced safety and mobility, enhance productivity and ensure secure wrapping results.Q: When should I consider adjusting the sealing temperature?

A: Adjust the sealing temperature (between 0C and 250C) based on the type and thickness of the shrink film used. The optimal temperature improves shrink quality and prevents film damage, accommodating different packaging requirements.Q: Where can the shrink wrap system be deployed effectively?

A: This machine is suitable for manufacturing plants, packaging facilities, warehouses, and distribution centers across India. Its robust build and mobility make it versatile for various operational layouts.Q: What is the process of operating the shrink wrap system?

A: Operation involves loading the chosen film roll (PVC, Polyolefin, or PE), setting conveyor speed and sealing temperature via the PLC control panel, and placing products onto the conveyor for automatic wrapping and shrink sealing.Q: How does the safety mechanism protect operators during usage?

A: Integrated safety features such as the emergency stop button and overheat protection safeguard operators by halting operations in hazardous situations and preventing temperature-related malfunctions.Q: What is the power consumption and electrical requirement for this system?

A: The shrink wrap system operates at 4.5 kW, requiring a voltage supply of 220-240V, 50/60Hz for effective performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+